Large-Scale Rotary Drilling Rig Price Breaking Down the Numbers

Large-Scale Rotary Drilling Rig Price Breaking Down the Numbers

Large-Scale Rotary Drilling Rig Price Breaking Down the Numbers

Today: rotary drilling rigs — the beasts that boil the earth and bore through rock. What do they cost? And why does the price swing so wildly?

What Is a Large-Scale Rotary Drilling Rig?

A rotary drilling rig is a machine used to drill into the earth by rotating a drill bit. The “large-scale” models are powerful:

-

designed for deep drilling (several kilometers or hundreds of meters),

-

heavy duty — handling massive loads,

-

used in industries like oil & gas, geothermal wells, mineral exploration, and infrastructure.

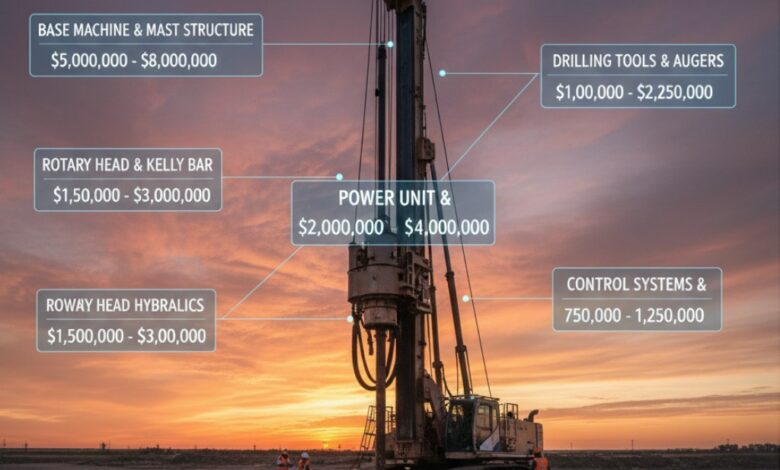

Before we talk price, it’s crucial to know what components matter:

| Component | Importance for Price |

|---|---|

| Engine power (HP / kW) | More power = bigger engine = higher cost. |

| Mast height / Derrick size | Taller derricks need more steel, logistics, etc. |

| Drawwork & hoisting equipment | Strength, precision, safety features increase cost. |

| Automation & control systems | Smart drilling tech adds cost. |

| Mobility (on tracks, skid, truck mounted) | Transportation & portability add complexity. |

| Brand / after-sales support / parts availability | Premium brands often charge more. |

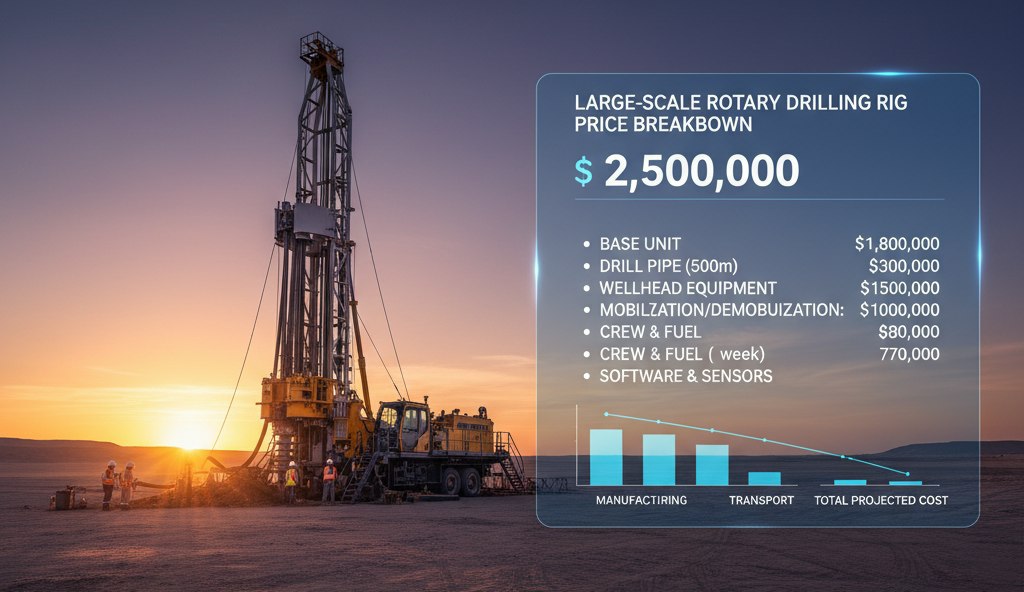

Price Ranges: What Buyers Are Actually Paying

Here’s a rough guide, based on market trends (global buyers, custom vs standard models):

| Type / Feature | Approximate Price Range* |

|---|---|

| Small “large-scale” rigs (e.g. 200-400 meters depth, modest power) | USD 0.5 million – USD 1.5 million |

| Middle tier (400-800 m, strong hoisting, decent automation) | USD 1.5 million – USD 3 million |

| Heavy duty, fully automated, deep drilling rigs (800 m+, high power) | USD 3 million – USD 6+ million |

*Prices vary hugely by country, shipping, import duties, currency, local labour, etc.

Key Factors That Make The Price Jump

What causes a rig to cost USD 3 million instead of USD 1 million? Here are the levers:

-

Depth and diameter capacity

Deeper and thicker holes require stronger components. -

Engine & Powertrain

Fuel efficiency, emissions compliance, turbochargers, auxiliary power systems. -

Automation / Remote Control Features

Sensors, real-time monitoring, remote operation—add sophistication (and cost). -

Mobility & Logistics

Transportable modules, track vs truck vs skid mounted: shipping costs skyrocket with size. -

Material & Build Quality

Steel grade, welding quality, durability—all affect both upfront cost and maintenance. -

After-sales & Support Network

Warranty, spare parts, training, servicing — all baked into the price. -

Customizations & Add-ons

Mud pumps, casing equipment, drilling fluids systems etc.

Case Studies & Market Examples

-

Brand A offers a 500-meter rig, diesel power, basic control panel: ~ USD 1.2 million delivered to site.

-

Brand B with 800-meter capacity, full automation, dual engines, shipped internationally: ~ USD 3.8 million.

-

Used vs New: A 5-year-old rig might drop 30-50% in price, but risk of downtime and maintenance misadventures rises.

If you’re considering procurement, weigh total cost of ownership (purchase + training + maintenance) over just the sticker price.

How to Budget Smartly When Buying a Rig

Here are actionable tips to avoid nasty surprises:

-

Define your application carefully

If you’re drilling geothermal wells vs oil/gas vs infrastructure, your needs differ greatly. -

Get multiple quotes

From local and international suppliers, ask for full breakdowns (engine, hoisting, mast, transport, duties). -

Factor in logistics & import costs

Transport, customs, installation, fuel. -

Check on‐site support & parts availability

A cheap rig with no local support can cost more in downtime. -

Consider financing / leasing

Sometimes paying for performance & uptime is smarter than owning outright. -

Plan for upgrades & future capacity

Buying slightly above current need can save retrofitting later.

Why Prices Vary by Region

-

Labor and steel costs differ sharply between countries.

-

Regulations and emissions standards: rigs compliant with the strictest standards cost more.

-

Currency fluctuations: importers often pay in USD/EUR but sell in local currency.

-

Transport distances to remote sites can double or triple costs for huge rigs.

Buying a large-scale rotary drilling rig isn’t just about how much it costs now, but what it will cost over time:

“The cheapest rig is the one that breaks.”